Your Entire Portfolio, in Your Pocket

Stop guessing and start seeing. A digital twin gives you a complete, interactive copy of every property you manage. It's the key to smarter remote oversight, faster maintenance, and confident decisions that save time and cut costs.

What This Actually Means for Your Team

25%

Faster Issue Resolution

60%

Fewer Site Visits

15%

Improved Planning Accuracy

10%

Longer Asset Lifespan

Complete Control, Less Travel

Managing properties across different cities in India comes with huge travel costs and logistical headaches. As the trusted choice for Matterport in India, we help you "walk" through any facility from your desk, saving you time and money. It’s the best way to keep a perfect, up-to-date record of every site in your portfolio.

- One Dashboard, All Properties: Access your entire portfolio from one simple, cloud-based platform.

- Slash Travel Costs: Cut down on the time and money spent on routine physical inspections.

- Standardize Your Oversight: Apply the same high standard of documentation to every single property you manage.

Smarter Maintenance, Happier Tenants

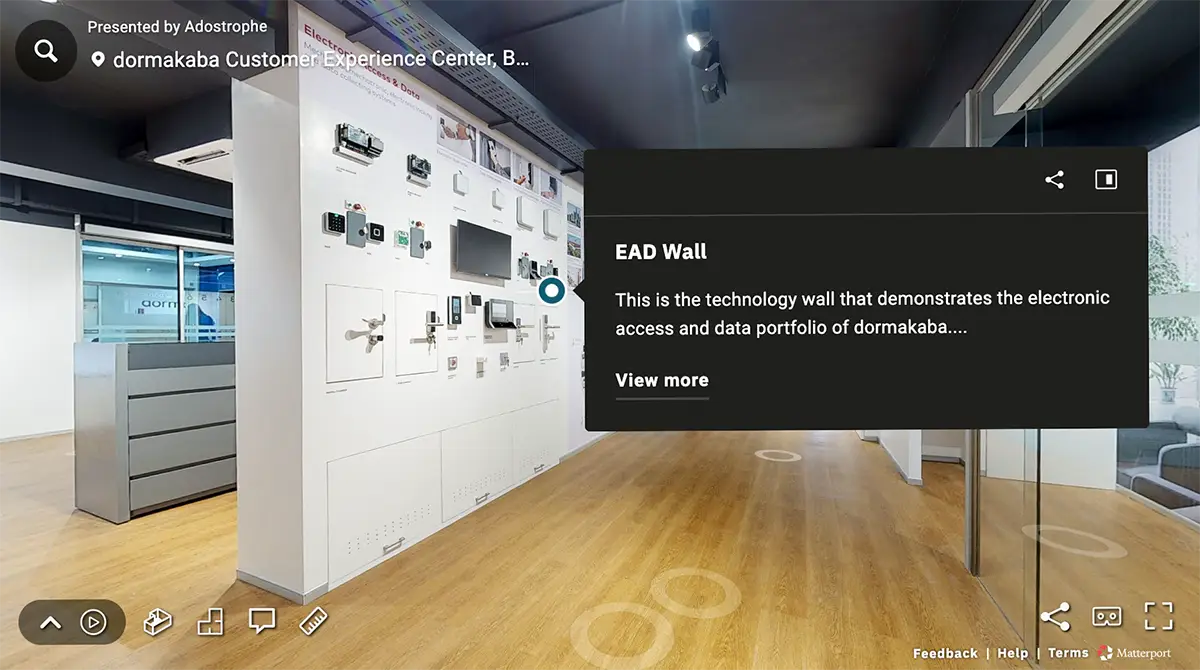

Imagine tagging every important piece of equipment in your facility. You can attach service logs, link to manuals, or even embed training videos. This lets your technicians "see" the problem before they arrive, boosting first-time fix rates and keeping your operations running smoothly.

- Put Data Where You Need It: Link manuals and service history directly to the asset in the 3D space.

- Diagnose Before Dispatch: Assess issues and identify the right parts before sending a team to the site.

- Coordinate with Clarity: Share the exact visual context with outside vendors for faster, more accurate quotes.

Make Confident Decisions with Your Space

Stop relying on old, inaccurate blueprints. A digital twin gives you dimensionally accurate 2D floor plans and 3D models you can actually trust. You can test new layouts, prepare for renovations, and see exactly how your space is being used, making sure every square foot is working for you.

- Get Accurate Floor Plans: Generate reliable schematic floor plans for architectural work or compliance.

- Visualize Before You Build: Digitally model new office or retail layouts before committing time and money.

- Eliminate Rework: Plan modifications using a perfect as-built record of existing conditions.

Simple Pricing & A Free Demo

Our pricing is a straightforward ₹10 per square foot. For businesses with a large portfolio or ongoing facility management needs, we are happy to provide a complimentary demo scan of a sample area. This allows you to experience the value and data quality firsthand before a larger commitment.

One Technology, Any Facility

Digital twins bring operational clarity to any space. Here’s how this technology adapts to different management needs across India.

For Residential Communities

In a large apartment complex, a digital twin is perfect for managing shared amenities. For a property like this one in Hyderabad, the facilities team can remotely oversee the library, gym, and theatre, ensuring these key spaces are always perfectly maintained for residents.

For Hospitality and Restaurants

In a busy restaurant, a digital twin ensures things run smoothly. It helps managers plan table layouts for big events, train new staff on service routes, and coordinate maintenance of kitchen and dining equipment with total precision, reducing downtime.

Frequently Asked Questions

How does a digital twin actually help me manage properties remotely?

Imagine walking through any of your properties without leaving your desk. A digital twin gives you a complete, interactive 3D model, so you can check on conditions, guide your on-site staff, and make decisions with total confidence. It saves a huge amount of time and money on travel, especially if you manage multiple sites.

How can this help my maintenance team work faster?

It's a maintenance supervisor's best friend. You can place interactive tags on any piece of equipment—like an HVAC unit or a water pump—and link them to maintenance logs or manuals. Your technicians can 'see' the problem before they even leave the office, making sure they bring the right tools to fix it on the first visit.

Can I use this for space planning and office layouts?

Yes, absolutely. A digital twin provides dimensionally-accurate floor plans and 3D models you can actually rely on. Your team can use this data to play with new office layouts, plan renovations, and see exactly how much space you're using. It takes all the guesswork out of optimizing your space.

Ready to Take Control of Your Operations?

Let's have a chat about how a Matterport digital twin can bring a new level of efficiency, precision, and remote capability to your entire property portfolio in India.